How does the density and tension control during weaving influence the final tactile properties and drape of clip jacquard fabrics?

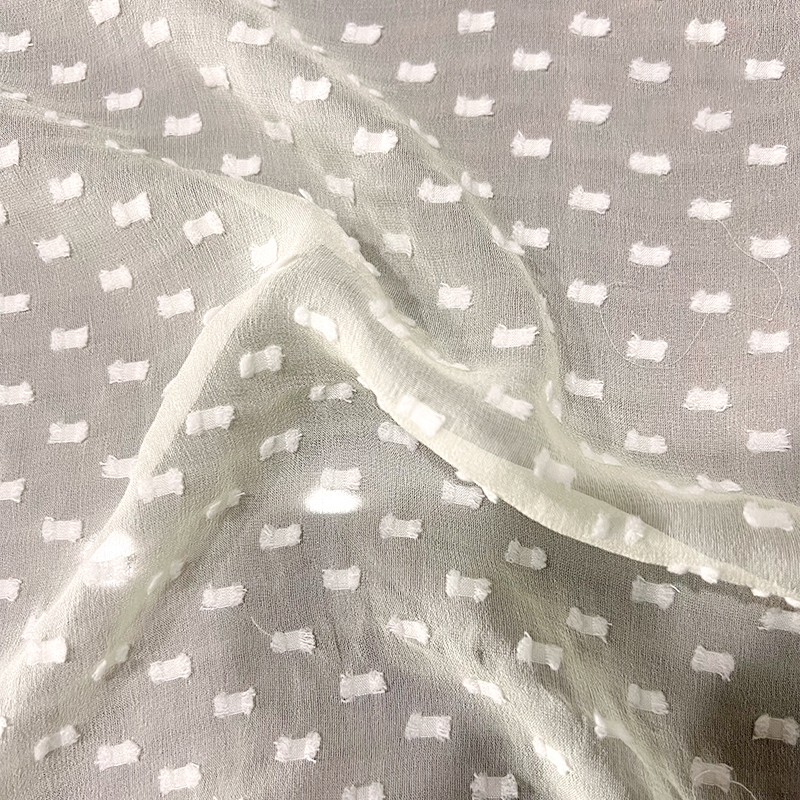

The tactile properties and drape behavior of clip jacquard fabrics are significantly influenced by the density and tension parameters applied during the weaving process. These two elements determine not only the structural integrity of the fabric but also how it feels to the touch and how it moves or falls when used in applications such as apparel, upholstery, or decorative textiles.

1. Fabric Density (EPI and PPI – Ends per Inch and Picks per Inch)

Density refers to how tightly the yarns are packed together in both the warp (lengthwise) and weft (crosswise) directions.

A higher fabric density results in a tighter weave, which increases the compactness and firmness of the fabric. In the case of clip jacquard, where parts of the floats are later clipped and removed to create a pattern, higher density helps retain the base fabric's dimensional stability even after some of the yarns are removed. The tactile feel of such a fabric is typically more structured, crisp, and firm, which may be ideal for formal garments, bags, or interior textile applications.

Conversely, a lower density weave allows for more openness and airiness in the structure, giving the fabric a softer, looser, and more breathable texture. This looser structure can enhance drape, making it more suitable for flowy garments or decorative elements where fluidity is desired. However, when applied to clip jacquard, a low-density weave may lead to issues such as fraying, uneven surface texture after clipping, or even distortion of the pattern, especially if the floats are long and the yarns are not well-supported.

2. Tension Control (Warp and Weft Tension Management)

Tension control refers to the level of force applied to the yarns during weaving. It has a direct effect on the uniformity and consistency of the fabric structure.

High tension in warp or weft yarns can cause the fabric to become too taut, resulting in a stiffer hand feel and reduced elasticity. This can lead to poor drape and a rougher surface texture, especially in areas where yarn floats are clipped and create differential thickness.

Low tension, on the other hand, may result in slack or uneven weaving, leading to undesirable effects such as fabric puckering, surface waviness, and misalignment of jacquard patterns. In clip jacquard, where pattern precision and visual clarity are critical, loose tension can reduce the definition of the design and result in inconsistent clipping.

3. Combined Influence on Tactile Feel and Drape

In clip jacquard fabrics, the tactile experience is twofold: you feel both the base fabric and the exposed surface patterns formed by the clipping of floating yarns. If the base is densely woven and tightly tensioned, the result is a more rigid, resilient structure, while a looser base will yield a softer, more pliable fabric with more movement and air permeability.

The drape, or how the fabric falls and flows, is largely a product of how flexible the woven structure is. High-density fabrics resist bending and form sharper folds, which can be visually appealing in structured applications. Low-density fabrics are more flexible and follow the body or contours more naturally, which is often preferred in fashion and soft furnishings.

4. Manufacturing Considerations

From a production perspective, balancing density and tension is essential to ensure that the clipping process doesn't compromise the integrity of the fabric. A well-balanced structure ensures that the floats are clipped cleanly without damaging surrounding yarns, maintaining a uniform appearance and feel.

Advanced jacquard looms often feature computerized tension regulation and pattern simulation, allowing manufacturers to preview and adjust these parameters to achieve the desired tactile effect and draping performance before full-scale production.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post