How does double-faced woolen goods fabric make it both warm and light?

Double-faced woolen goods fabric achieves both warmth and lightness simultaneously, primarily owing to its material and manufacturing techniques.

The material of double-faced woolen goods fabric usually consists of high-quality natural fibers such as wool and cashmere. These fibers inherently possess excellent insulating properties, capable of absorbing and retaining a significant amount of air, forming a warm barrier that effectively blocks the intrusion of cold air from the outside. Simultaneously, these fibers are very lightweight, ensuring that the fabric remains warm without feeling bulky.

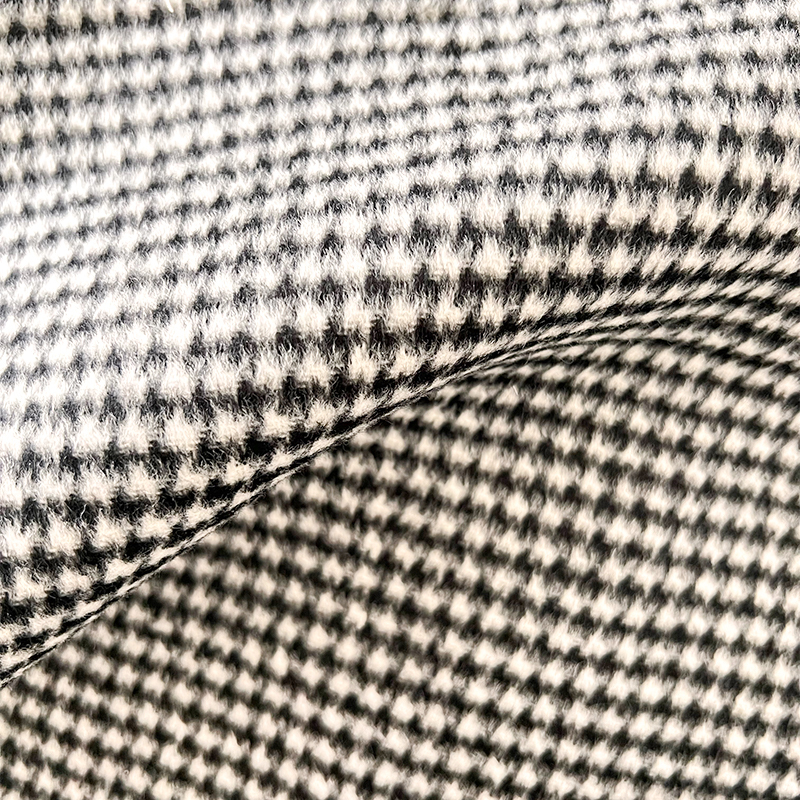

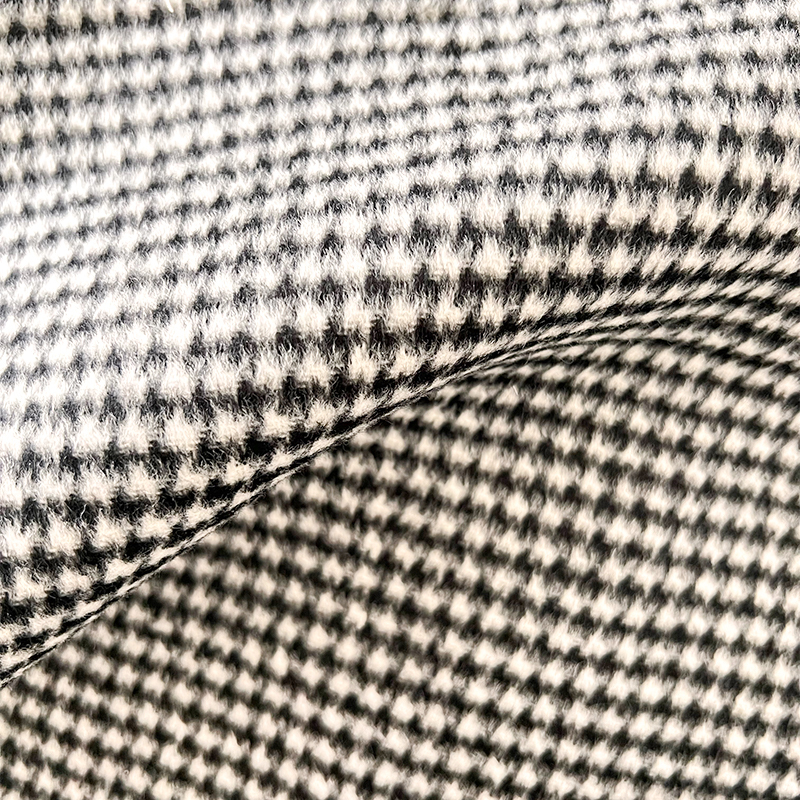

The manufacturing technique of double-faced woolen goods fabric is also crucial in achieving warmth and lightness. It is woven from two independent layers of fabric connected by yarn in the middle, rather than using adhesives or other methods. This structure ensures the fabric's insulation while avoiding the heaviness associated with adhesive techniques. Additionally, during the textile process, special treatments such as shrinking and pressing can make the fabric denser, softer, and further enhance its insulating properties while maintaining a lightweight texture.

Double-faced woolen goods fabric also emphasizes color selection and fabric density. The double-faced design enhances the visual richness of the fabric, and different thicknesses of yarn can be chosen to adjust the fabric's density according to needs, thus controlling the weight of the fabric while achieving insulation.

These factors together make double-faced woolen goods fabric widely applicable in garment production, especially suitable for making winter coats and other garments that require both warmth and lightness.

The material of double-faced woolen goods fabric usually consists of high-quality natural fibers such as wool and cashmere. These fibers inherently possess excellent insulating properties, capable of absorbing and retaining a significant amount of air, forming a warm barrier that effectively blocks the intrusion of cold air from the outside. Simultaneously, these fibers are very lightweight, ensuring that the fabric remains warm without feeling bulky.

The manufacturing technique of double-faced woolen goods fabric is also crucial in achieving warmth and lightness. It is woven from two independent layers of fabric connected by yarn in the middle, rather than using adhesives or other methods. This structure ensures the fabric's insulation while avoiding the heaviness associated with adhesive techniques. Additionally, during the textile process, special treatments such as shrinking and pressing can make the fabric denser, softer, and further enhance its insulating properties while maintaining a lightweight texture.

Double-faced woolen goods fabric also emphasizes color selection and fabric density. The double-faced design enhances the visual richness of the fabric, and different thicknesses of yarn can be chosen to adjust the fabric's density according to needs, thus controlling the weight of the fabric while achieving insulation.

These factors together make double-faced woolen goods fabric widely applicable in garment production, especially suitable for making winter coats and other garments that require both warmth and lightness.

中文简体

中文简体 Français

Français Deutsch

Deutsch italiano

italiano

previous post

previous post